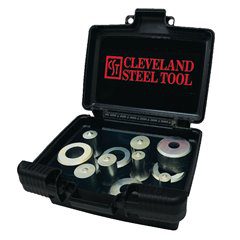

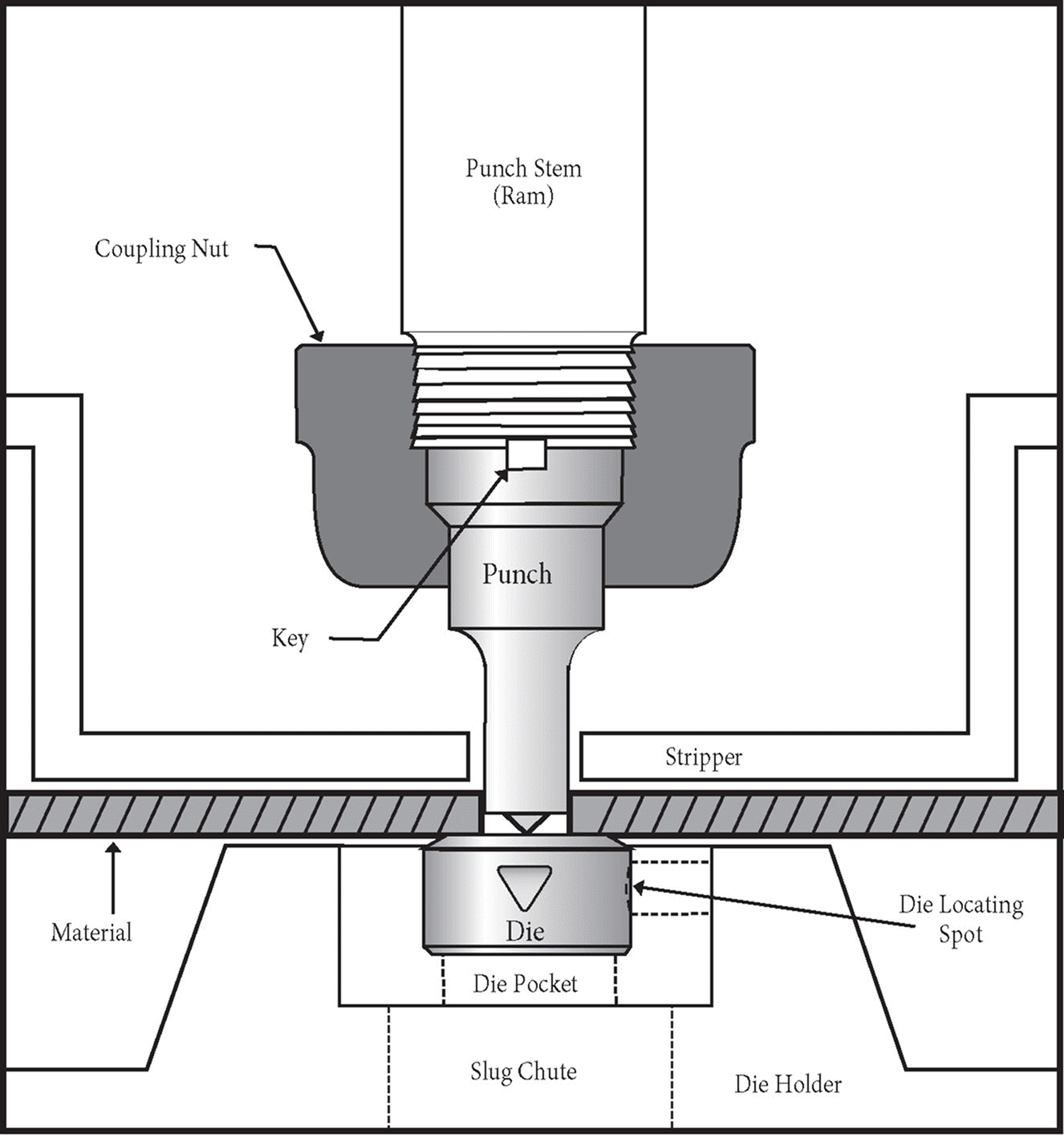

- Ironworker Tooling

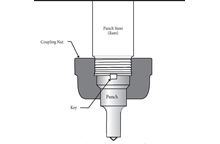

Ironworker Tooling

Whatever your application, Cleveland Steel Tool can help you make the hole you need. We have a huge selection of Punches and Dies in Stock, and offer 24 hour turnaround on most special sizes.

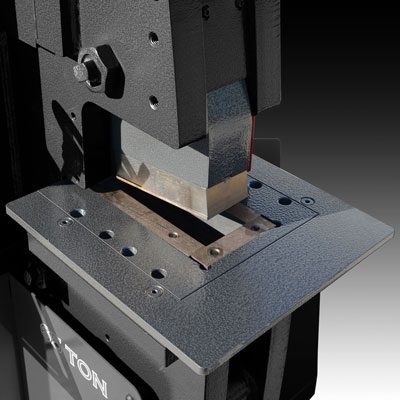

- Ironworker Machines

CST Ironworker Machines

We carry a full line of Ironworkers to suit your metalworking needs from 40 Ton to 120 Ton Capacity

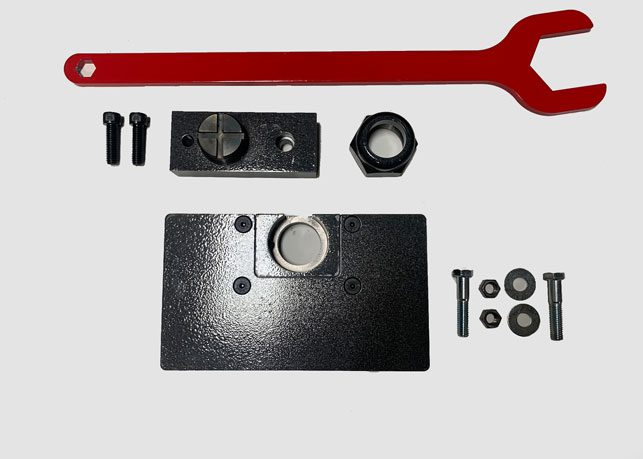

- Portable Punching Unit

Portable Punching Units

Our Porta-Punch is the quickest and easiest way to punch up to 13/16" Round Holes in 1/2" thick mild steel with a MAXIMUM tensile strength of 65,000 psi.

- Annular Cutters & Magnetic Drills

Annular Cutters

We offer a full range of annular cutters for a wide variety of drilling applications. Our annular cutters fit almost any magnetic drill and ship with a center pin.

High Speed Steel Fractional Sizes

Carbide Tipped Fractional Sizes

High Speed

Steel Metric

Countersink

CuttersMagnetic Drills

Compact and lightweight design in a portable drill to make your job site or production facility more productive.

- Shop By Machine Make

- More

Cleveland Steel Tool - Manufacturing Punches, Dies, Blades and Custom Tooling for over 100 years!