CST 75 Ton *DISCONTINUED – PARTS ARE AVAILABLE*

From production to maintenance and repair or anything in between.

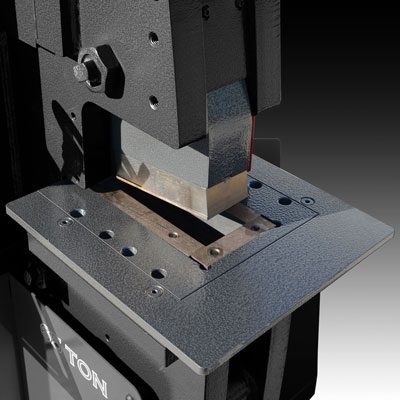

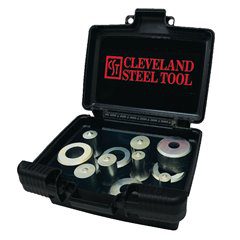

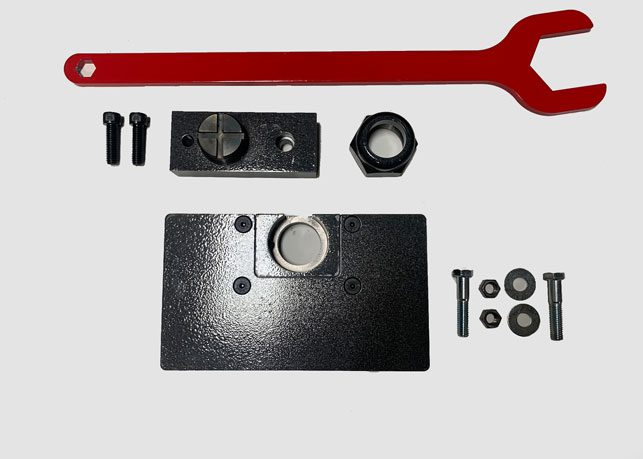

Comes equipped with punch station including a pedestal die table, angle shear, up to 14″ flat bar shear, dedicated coper notcher. Choose from the multi-shear, angle notcher, 12″ brake, rod shear, pipe notcher, or oversized punching attachment. Install the PowerLink System and maximize your shop capabilities by choosing the 10 Ton Pipe and Tube Bender, or one of our shop presses.

From production to maintenance and repair or anything in between.

Comes equipped with punch station including a pedestal die table, angle shear, up to 14″ flat bar shear, dedicated coper notcher. Choose from the multi-shear, angle notcher, 12″ brake, rod shear, pipe notcher, or oversized punching attachment. Install the PowerLink System and maximize your shop capabilities by choosing the 10 Ton Pipe and Tube Bender, or one of our shop presses.

Technical Specifications:

| Rated capacity | 75 Ton 65,000 psi tensile strength |

|---|---|

| Number of work stations | 4 |

| Throat Depth | 10″ |

| Maximum Capacity | 1-1/16″ dia. thru 7/8″ plate |

| Largest standard punch | 1-1/16″ punch |

| Open height | 8-3/4″ |

| Closed height | 6-15/16″ |

| Stroke | 1-13/16″ |

| Table Size | 6″ x 10″ |

| Hydraulic System | 17 gallon reservoir, 3-1/2″ cylinder |

| Standard Motor | 7.5 HP, 3 Phase, 208V or 230V – 22 amp |

| Optional Motor | 7.5 HP, 3 Phase, 460V – 11 amp |

| Optional Motor | 7.5 HP, 3 Phase, 575V – 8 amp |

| Optional Motor | 5 HP, 1 Phase, 208V or 230V – 23 amp |

| Optional Motor | 7.5 HP, 1 Phase, 208V or 230V – 36 amp *required for PowerLink System |

| Dimension | Base 50″ W x 45″ D x 60-1/4″ H |

| Shipping Weight | 4,100 lbs. |

Reviews

There are no reviews yet.